Vibrating Screen - Top Separator machine

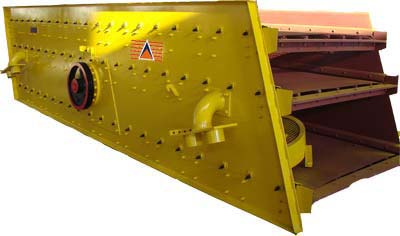

Vibrating Screen

Vibrating screen is a kind of sieving equipment with multilayer and high efficient. It is of long streamline, clear screening for different specifications.

SBM as a vibrating screen manufacturer in China, supply Double-deck sifter or triple-deck vibrating screen for sale in India, Germany, Ghana, Indonesia, Vietnam, USA, Australia, Nigeria, South Africa etc.

Vibrating Screen Construction

SBM Vibrating Screen is the circular Screening machine mainly consists of screen, transmission part and main unit including screen box,supported device and exciter.

Vibrating Screen Application

Vibrating Screen is widely used for grading and screening building aggregates, sand, mine ores. In stone quarry, or mine ore beneficiation, it work with crusher machines for crushing and screening.

Vibrating screen for sand gravel making

It is used to screen out sands with different size. According to the requirement of size, choose the right sieve mesh. In screen grading, the sand is separated mechanically on screen plates.

Vibrating screen for ore mining

In the mine ores mining project, such as iron ores beneficiation plant and copper, chrome mining plant, it is the screening machine to screen out the appropriate small crushed ores size.

Vibrating Screen Main Features and Benefits

- This series uses eccentric block to produce strong exciting force.

- Crossbeam and the main body are connected with high strength screw bolts. So they have the features of simple structure and easy maintenance.

- Adopts tire coupling with capability of flexible connection and stable operation.

- It adopts the structure of small amplitude, high frequency, large obliquity to make the screen hold the capability of high efficiency, large handling capacity, long life span, low consumption, and little noise; you will find this series screen optimized for your demands.

Vibrating Screen working principle

Vibrating Screen moves round. It has multi-layers and is of high efficiency. The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

In screen grading, the material is separated mechanically on screen plates. Rolling bearings in vibrating screen are stressed by high, mostly shock-type loads. Moreover, the bearings, while rotating about their own axis, perform a circular, elliptical or linear vibrating motion. This results in high radial accelerations which additionally stress the bearings, and especially the cages, considerably. The operating speeds are usually very high. As a result, the bearing temperatures are up to 20 to 30 degrees Kelvin higher than in normal applications. In addition, considerable misalignments between the bearing locations and considerable shaft deflections have to be accommodated.

Vibrating Screen Specification

| Type | Screen Spec (mm) | Layers | Sieve Pore (mm) | Max. Feed Size (mm) | Capacity (t/h) | Power (KW) | Screen area (m2) |

| 2YA1237 | 1200×3700 | 2 | 3-50 | 200 | 7.5-80 | 5.5 | 3.6 |

| 3YA1237 | 1200×3700 | 3 | 3-50 | 200 | 7.5-80 | 7.5 | 3.6 |

| 2YA1548 | 1500×4200 | 2 | 5-50 | 400 | 50-208 | 15 | 6.3 |

| 3YA1548 | 1500×4800 | 3 | 5-50 | 400 | 50-250 | 15 | 7.2 |

| 3YA1848 | 1800×4800 | 3 | 5-80 | 400 | 50-300 | 18.5 | 8.64 |

| 3YA1860 | 1800×6000 | 3 | 5-80 | 400 | 50-350 | 22 | 10.8 |

| 3YA2160 | 2100×6000 | 3 | 5-100 | 400 | 100-500 | 30 | 12.6 |

| 2YA2460 | 2400×6000 | 2 | 5-150 | 400 | 150-700 | 30 | 14.4 |

Vibrating Screen operation note

Operation points:

- The operator on duty should read records, and conduct general inspection before work. Check tensioning extent of the V-belt, the oil level of vibrator, check the surface tension situation.

- Stared followed the order of process system.

- When working, use visual, hearing tests and screening exciter boxes work. After stopping touch the bearing caps and check bearing temperature rise situation.

- It should be stopped followed the order of process system. Except special requirements, prohibite to continue to sieve after stoping.

- When shift relief, put down the state technology and discovery to duty records.

Attachment:

![]() Vibrating Screen PDF Download

Vibrating Screen PDF Download